Prototypes are a crucial part of the design process before full manufacturing can occur. They help to visualize what’s working and what’s not within a product.

Without a successful prototype, there is little chance that the product will be manufactured and sold. However, the first step in making a working prototype is finding a machine shop that can do the work for you.

There are many prototype machine shops around the world, but finding the right one can still be tricky. We’ve created the ultimate guide to finding the right shop for you.

Can Complete Your Manufacturing Project

First and foremost, you need to make sure that the large machine shops you’re looking into have the capabilities to create what you need.

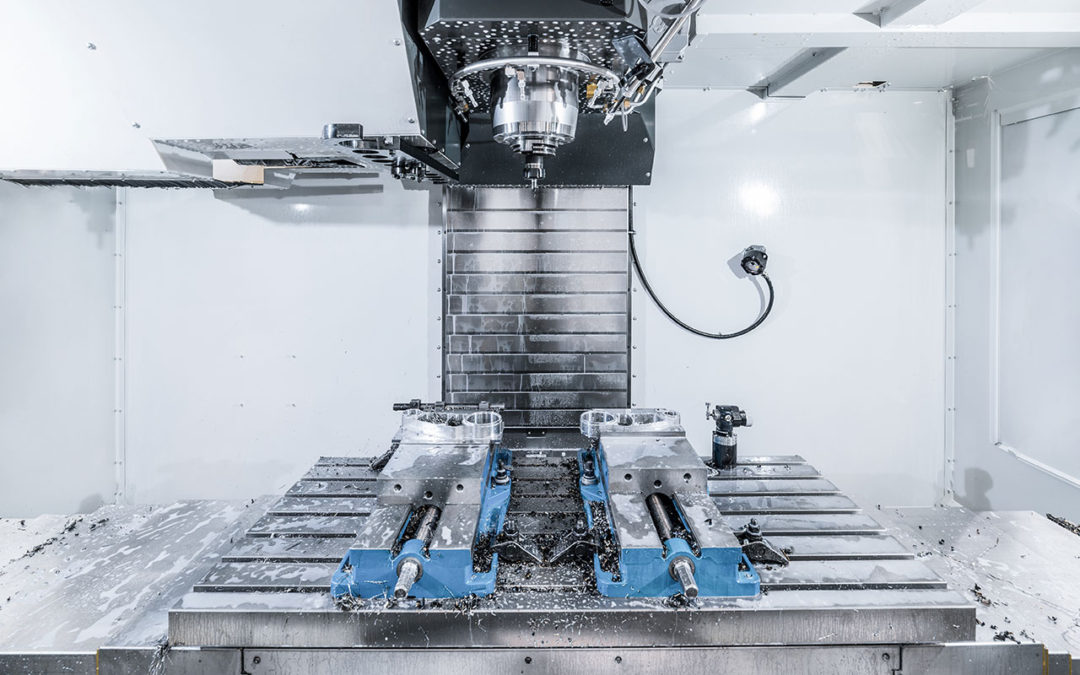

There are all different types of milling machine options Each has unique capabilities and can only work within those. The operators of these machines will be able to work with you to decide if your project is possible with them or not.

Sometimes, a prototype may also need a few machines in order to be fully produced. In that case, finding a shop that has all of the right machines is even more critical.

You want the prototype development and production to move quickly and seamlessly. This will help you move on to production as fast as possible, which is the end goal. Making sure ahead of time that your piece can actually be produced in the shop eliminates many delays.

Clear Process Documenting System

The making of a prototype isn’t always a cut and dry process. It usually involves at least a few different steps and will likely take some time before it’s fully completed.

And, generally, you aren’t the person who is actually doing the producing. You likely won’t even be on-site during most, if any, of the process. That can be difficult to wait and see how things work out.

So working with a prototype machine shop that keeps detailed records as things are being produced can bring great peace of mind.

One way this is done is through a system where each piece is given a barcode that can be scanned and check up on at any time. Throughout the whole production process, you can see how things are going and what’s coming next.

Technicians Have Proper Training

Since you won’t be the person doing the actual manufacturing of your prototype, it’s really important to check out the credentials and training of the operators.

It’s likely that the operator will need to program the machines in order to get them to do exactly what you need. The operator will also need a healthy understanding of different materials, their strengths and weaknesses, and how to work with them correctly.

In this manufacturing process, the prototype machine operators become a very important resource and an asset to your success.

So you should really make sure the ones you choose to work with will be able to help you in any way you might need. That will look different for everyone, but having a clear understanding of what you need and then basing your choice on that is a good place to start.

Work in a Variety of Quantities and Materials

Obviously, not all prototypes are going to be the same. They aren’t all even in the same category. A prototype could be for any project, and the possibilities are literally endless.

So one of the most important steps in your design process is to figure out the best material to use.

Once you’ve figured that out, you’ll need to check with your shop to make sure their milling machine can work with that material. Not all machines or operators work well with all types of materials, so this is an important thing to check.

It’s also really important to make sure that you can get just one or 1,000 of what you need.

Different projects will require a different number of prototypes, so understanding what’s possible will help you plan better moving forward.

Fits Within Your Budget

Getting into product development can be an expensive venture. There are so many initial costs that go into a successful launch, from design to manufacturing to marketing to shipping. All of those things need to be worked into your budget.

Prototypes are a crucial element to a project but not the only element, so sometimes they get left out of budgets.

Getting an estimate for the cost of prototype production, and even a quote for a few scenarios, can help you better manage the funds you have. This will help you to understand how many you can get and how often you can try again for the right part.

Many shops are happy to lower cost for prototypes in hopes that you’ll choose them for full manufacturing, which can be a major boost to the overall budget.

Acceptable Turnaround Time

In the grand scheme of manufacturing and prototype production, the timeline isn’t often very quick. All of the steps take time for it all to come together.

But you don’t want that timeline to be extended longer than it needs to be, especially if you have other deadlines to meet within your overall project.

So it’s helpful to get an estimated time of completion and delivery before you begin working with any prototype machine shops.

The operators should be able to let you know what steps will need to be taken and approximately how long each one will be. This just helps you plan the whole project out more accurately.

Find the Right Prototype Machine Shops

Creating a new product is thrilling and exciting! It’s taking an idea you had and bringing it to life.

One of the most important parts of that process is working with prototype machine shops to get the product just right. These prototypes help you to tweak the product to be exactly what you have envisioned.

When you’re ready to get to work creating your prototype, contact us and we’ll be able to help you get started!