Does your product require parts to be fabricated out of metal? Are you looking to hire a CNC machine shop but don’t know where to start?

It can be a tough task since CNC machining is a highly-skilled industry. Not to mention, there is no shortage of options in today’s marketplace.

How do you know if you’re using the right machine shop for you? We have 5 questions to ask to help you avoid CNC machine shop remorse.

Let’s go over them now.

1. Do They Have Experience?

Like with anything else, you’ll want to make sure the CNC machine shop you’re working with is experienced in their trade. More importantly, you want to make sure the CNC operators have experience manufacturing the components specific to your product or industry.

This type of specialized experience shows that the operators will be able to deliver the parts to your product with the highest industry standards. In addition, it helps you to put your mind at ease knowing whatever is produced by the shop will not only meet the standards of the shop supervisors but your quality control standards as well.

2. What Are People Saying?

Does the shop you’re considering have references or reviews? If you can’t find anything online, don’t be afraid to ask for names and phone numbers of companies they’ve worked with in the past.

It doesn’t hurt to begin your search by asking around. Other businesses within your industry, or maybe other vendors that need a machine shop, could have a hidden gem for you. Referrals can be the best form of advertising, no matter the industry.

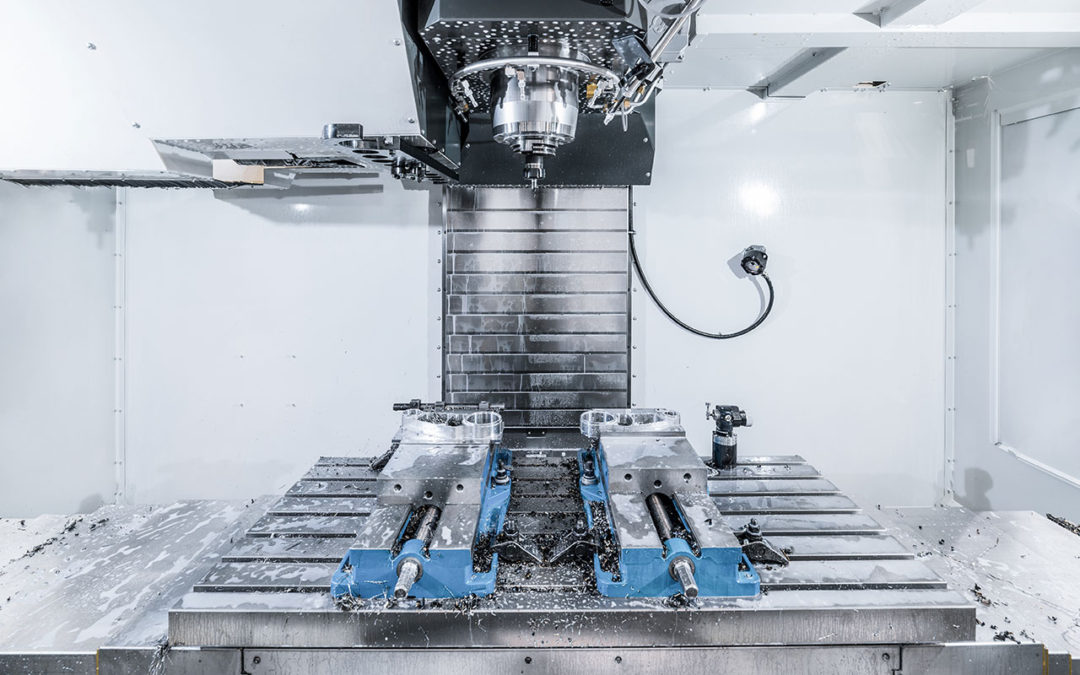

3. What Are Their Processes?

When you want to hire a CNC machine shop, it’s important to have your end goal in mind. Machine shops use different processes depending on the results they’re looking to achieve and the material they’re using. You’ll also want to factor in whether you need a smooth or rough surface for your components.

Any of your desired results could be achieved by a qualified machine shop, but knowing what you want and communicating it to your supplier will go a long way in selecting the right shop.

The shop you’re considering should also have a variety of machines. Some shops, especially ones that are just starting out, may have older equipment. These machines are solid, but you may want to pursue a shop that has newer technology.

All of that depends on the type of materials you need to use, and the precision your components need to have.

4. Is Their Work High Quality And Consistent?

This is where your list of references will come in handy. Call them and ask them how the quality of the shop’s work was. Was it to their Quality Control standards, or did they keep having to get parts re-machined?

Are they capable of handling the type of work you require? Can they handle the volume you require? Do they offer mass-production or are they primarily a custom order shop?

You’ll also want to make sure that they can provide you with consistent work. Ask past customers if work was delivered on-time, and was the work the same every time. This is especially true if you’re dealing with a component of a bigger product.

That particular part should look, feel, and fit into the larger product the same way every time.

Another thing to look for when searching for a machine shop is an ISO certification. This can weed out a lot of shops right off the bat. The ISO certification will ensure you’re dealing with a shop that adheres to the utmost quality standards and is equipped to give you the machined components you are looking for.

5. How Is Their Customer Service?

Ask the shop you’re researching what their process is for handling customer orders. How transparent are they in this process? There’s more to running a machine shop than machining alone.

Whichever shop you choose should have a process laid out for how they intake, handle, and deliver your order. This shows you that they’re organized, and they’re thinking about your needs and deadlines.

What is their workforce like? Do you feel like they have enough people to complete your orders? Are the people on their team receptive?

In addition to how they handle their customers, they should also be providing you with prototypes or samples. Many shops don’t offer sample pieces, but these are very important if you’re doing a large scale production.

Failure to produce any samples or prototypes could cause you to be unhappy with the design, or even cause a slow down in the production process.

Reminders Before You Hire a CNC Machine Shop

In addition to what we’ve discussed above, there are a few things you’re going to want to consider before pulling the trigger on hiring a shop.

First, make sure to have an alternative material for your component. Sometimes the shop can’t get the material you were originally looking for, or it would raise production costs. Having an alternative in mind will help things to be more efficient.

Next, be specific. Express, in detail, what you want out of the machined parts the shop is making for you. Clearly communicating your precision and quality standards will go a long way in helping the project move along.

Finally, know how your product will be developed. If you’ve designed this part yourself, you need to consider how the product as a whole will be developed. If you design the part “in a vacuum” without considering how it relates to the project as a whole, you could be sent back to the drawing board a lot.

This will increase your production costs.

Final Cut

We’ve given you a lot of things to consider when you go to hire a CNC machine shop. Ultimately, all the research up-front will ensure a happy, efficient relationship on both sides.

If you take the time to properly vet and interview your potential machine shop, you could find one that will be a partner in your business for years to come.

If you’re looking for any more advice on machining, tools, or anything industrial, just check out our blog or drop us a line.